Data centre trends and countertrends, and their impact on UPS systems

In this article, Ian Jackson, Managing Director at Kohler Uninterruptible Power Ireland, explains how large and micro-scale data centres can, despite their diversity, benefit from modern, modular UPS topology-based solutions.

The Internet of Things (IoT) is creating a sustained and exponential growth in data, due to both large project sizes and an ongoing surge in IoT adoption. According to Vodafone’s fifth annual IoT Barometer[i] report, published in 2017, the percentage of companies with more than 50,000 connected devices had effectively doubled in the previous year – and the latest IoT Barometer[ii], appearing in February 2019, shows a surge in adoption leading to 34 percent of companies globally now using the IoT.

This size and rate of growth must clearly be having an impact on data centres, their internal ICT equipment and other components such as UPSs also critical to their operation. But how exactly is the data landscape evolving, and how can UPS designers and users meet the challenges being created?

To answer these questions, we start by reminding ourselves of the basic IoT model, and then give an example of a typical application; one that reflects today’s IoT realities. Next, we can look at the data centre environments being created by such applications, the challenges they create for the UPSs within, and how modern, modular UPS topology can be used to overcome these.

The IoT model

An IoT infrastructure gives us an opportunity to gain previously unattainable insight into the world around us – or part of it, at least – and accordingly take actions that bring new benefits such as greater energy efficiency, more productivity, or reduced maintenance downtime. To achieve this, large numbers of sensors, often distributed over a wide geographical area, collect data from machines, people, vehicles, farmland or other edge locations, including wind farms as mentioned below.

For this data to be useful, it has to be sent back to a central processing location, typically large-scale and cloud-based, where it can be integrated, analysed and archived. Recommendations for action can then be generated, either in the form of human-readable reports, or as control commands sent back to actuators around the edge.

The collected edge data comprises various analogue, digital, video or audio signals, depending on the application. At the very least, these must be aggregated, formatted for data transmission, and routed through a gateway onto a long-haul network back to the cloud data centre.

However, it’s often desirable to process the signals rather than merely package them. Local processing eliminates the latency associated with a return journey to a remote server, so fast, responsive control of local equipment becomes possible. Data security and reliability are also improved. Another key benefit is that the amount of data to be loaded onto the network is reduced; an increasingly important consideration as IoT traffic volumes increase.

This level of processing can be provided by one or more micro data centres distributed around the application’s edge.

IoT example – wind farms

Wind energy is one environment that can benefit from both edge micro data centres and centralised cloud resources. Wind turbines are extremely complex devices, often placed in wild conditions, out at sea or in remote land-based locations. Each turbine may include up to 1,000 sensors and actuators; integrating strain gauges, bearing monitors and power conditioning technology. Controlling the turbine is a sophisticated job requiring many cooperating processors closing high-speed loops and implementing intelligent monitoring and optimization algorithms.

While these tasks can best – or only – be handled by local processing, there may also be a need to balance the performance of possibly large numbers of turbines distributed across the wide geography of a wind farm. Centralised, IoT-based visibility and control becomes essential to complement the local fast processing capability.

Impact on UPS requirements

While micro data centres and cloud data centres are very different environments, both contain IT and communications equipment that needs clean, uninterrupted power.

Micro data centres can be in remote locations where access is difficult, time-consuming and expensive – yet, in spite of the maintenance challenge, their application often demands very high-power availability. They may be deployed into locations that are space-constrained and/or environmentally challenging; minimising heat generation may become a priority. An IoT infrastructure may comprise multiple micro data centres, making hardware standardisation an issue.

The centralised cloud resource will more likely be large- or hyperscale, often providing a colocation facility for many users. Loads will be variable, and subject to rapid change through virtualisation or as servers are removed or added. Power problems are unacceptable, due to the high number of users that will be impacted by any downtime. On such large scales, energy efficiency performance will be highly visible and open to critical review from all stakeholders.

Modular UPS technology

Although these requirements are disparate, they can be met by suitable deployments of modular UPS solutions – so what do these comprise?

Traditionally, UPSs used monolithic, transformer-based designs of considerable size and weight. If you wanted 60kVA capacity, for example, you would fulfil this with a floor-standing 60kVA UPS unit. And for N+1 redundancy, two such units would be needed.

However, with advances in power semiconductor technology, transformerless solutions became possible – and this meant that complete UPSs could be built as relatively small, rack-mounting modules rather than as large monolithic units. The benefits for both scalability and availability are highly significant.

For example, the 60kW requirement of above could be met by a 19” rack populated with three 20kVA modules. N+1 redundancy could be achieved by adding a fourth 20kW module. Utilisation is 75 percent, compared with just 50 percent for the traditional solution. Scalability is easy, as capacity can be incremented by plugging in another module. Many modular UPSs offer hot swappability, so modules can be exchanged without interrupting power to the critical load.

‘Six nines’, or 99.9999 percent availability becomes possible, as high availability is related to both maximised mean time between failures (MTBF) and minimised mean time to repair (MTTR). MTBF can be increased through redundancy, while MTTR can be reduced with hot swappability. Repair times using module replacement can be reduced to about half an hour, compared with the six hours or so typically need for an in-situ repair of a monolithic system.

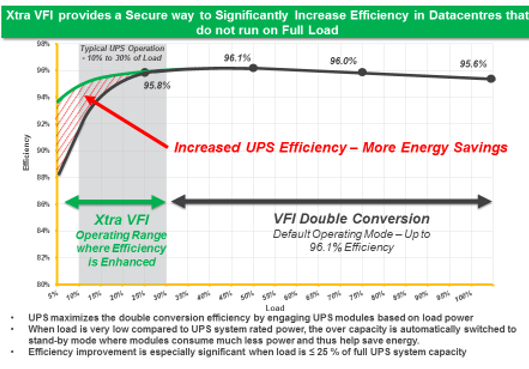

Efficiency is improved in a couple of ways. Firstly, transformerless technology is inherently more efficient than transformer-based over a wide operating load range. Secondly, some modular UPSs offer an energy-saving feature called Xtra VFI. This prevents UPS modules from running at low loads, below 25 percent, where their efficiency drops away. It operates by automatically adjusting the number of active modules to meet changing load requirements. Fig.3 shows how Xtra VFI can improve operating efficiency.

A practical solution for micro data centres …

Kohler Uninterruptible Power’s (KUP’s) ABB UPScale UPS modular system can be used in micro data centres. It’s available in rack-mountable form, so a complete power protection solution comprising UPS, battery and communications can be integrated into any manufacturer’s 19” racking system, including equipment that has been IP rated to provide protection from dust and water ingress. Providing up to 80kW, or 60kW N+1 using 10 or 20kW hot-swappable modules, the system is suitable for integrated IT, telecom or other applications. It is also available in a Tower version, with capacities from 10 to 200kW, or 180kW N+1. Maximum power density is 472kW/m2, and cabinets can be paralleled to increase capacity up to 400kW.

With a high energy efficiency of up to 95.5%, heat loading in a confined environment is minimised. High availability is assured through N+1 redundancy, while a stock of standard modules can be held for cost-effective, easily-managed support of multiple micro data centres.

…and another for large-scale facilities

KUP’s ABB Conceptpower DPA500 UPS system is designed for large data centre environments. An ABB Conceptpower DPA500 rack can accept up to five hot-swappable 100kW modules, for up to 500kW capacity – or 400kW with N+1 redundancy. Up to six racks can be paralleled for horizontal scalability, to provide a total capacity of 3MW. The system provides Six Nines (99.9999 percent) availability, with online energy efficiency of up to 96 percent (or ≥ 99 percent in Eco mode).

The system also features the Xtra VFI mode, to maintain efficiency even during under-loading.

Conclusion

In spite of edge micro data centres’ and central large-scale facilities’ very different environments, they make a number of common demands on their UPSs; extremely high reliability and availability, advanced energy efficiency, and easy scalability. Power systems designers and users can meet these requirements using appropriate implementations of modular UPS technology.

References

[1] https://www.computerweekly.com/news/450427112/Large-scale-IoT-deployments-double-in-12-months

[1] https://www.vodafone.com/business/news-and-insights/white-paper/vodafone-iot-barometer-2019

Leave a Reply